Wartsila

LNG Tank Gauging Systems

Wartsila Tank Control Systems (formerly Whessoe S.A.) specializes in tank gauging systems for LNG and LPG applications. LNG has evolved into a major source of energy for the future, and Wartsila Tank Control Systems can supply your site with the only turnkey LNG tank gauging and storage management system available. Through Wartsila Tank Control Systems’ LNG Master (sold under license by Gaz de France), Warsila can offer dramatic cost savings through proper LNG stratification management.

Wartsila Tank Control Systems also manufactures unique "in-tank" LPG safety shutoff valves that insure that your safety shutoff valves remain intact and operational, even in the event of an accident that damages or destroys piping, valves and controls that are external to the tank.

LNG Tank Gauging and Management Systems

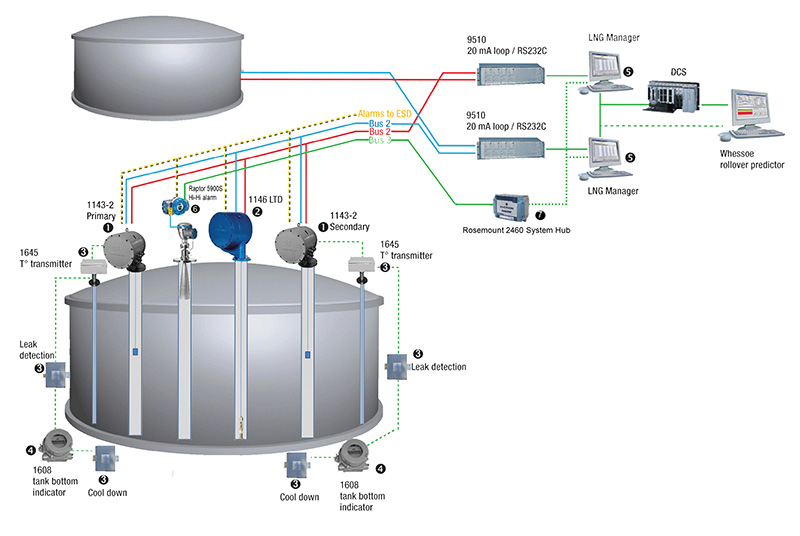

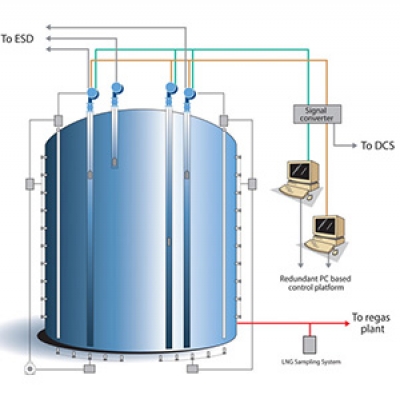

Reliable, accurate data helps operators to take sound operational decisions that directly impact operating costs and plant safety. Wartsila Tank Control Systems is the world's largest supplier of LNG tank gauging systems, offering the only complete, turnkey LNG tank gauging solution available. LNG densities and temperatures, LNG liquid levels, tank temperature probes and LNG leak sensors are all monitored on a fully redundant "LNG Manager" communications platform providing full system information and management capabilities to the operators. "LNG Master", developed by Gaz de France, provides LNG stratification management and roll-over prediction that allows operators to utilize stratification as a tool to reduce LNG boil-off and dramatically reduce LNG storage operating costs!

LNG Tank Gauging and Management Systems

Safety

LNG is a "dynamic" liquid. If not controlled, it can generate a dangerous situation.

Inventory Management

Storage of LNG is a business. Exact data on mass contents are imperative.

Cost Control

Reliable, accurate data helps operators to take sound operational decisions that directly impact the business results.

Wartsila Tank Control Systems is the world's dominant supplier of LNG tank gauging systems, offering the only complete, turnkey LNG tank gauging solution available. LNG densities and temperatures, LNG liquid levels, tank temperature probes and LNG leak sensors are all monitored on a fully redundant "LNG Manager" communications platform providing full system information and management capabilities to the operators. "LNG Master", developed by Gaz de France, provides LNG stratification management and roll-over prediction that allows operators to utilise stratification as a tool to reduce LNG boil-off and dramatically reduce LNG storage operating costs!

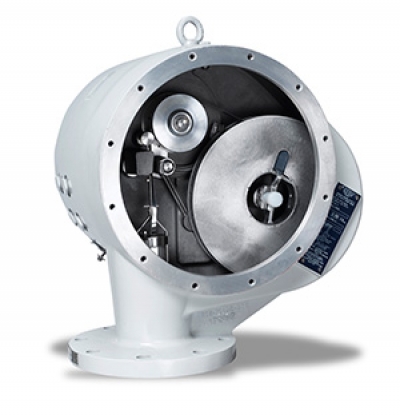

Model 1146 LTD Servo Gauge

- Monitors LNG density/temperature at multiple levels

- 0-65 meter operating range with 250 datapoints

- High accuracy, repeatability and reliability

- Designed for continuous automatic operation

- Full redundancy: Dual loop and multiple control stations

- Tape material: SST.316l, Tefzel coated

- Automatic tape contraction compensation

- Low service requirement

- Single control platform

- Warranty: 3 years

- Saves energy

- Directly linked to your DCS system

- Low installation/wiring cost - just 5 cores, no marshalling cabinet required

- ATEX Certified Zone 1, CSA/UL Pending

Model 1143 Cryogenic Servo Level Gauge

- Small and compact

- Easy to Install (5 cores: power, ground, signal)

- Continuous indication of:

- Level (local and remote)

- Temperatures

- Diagnostics

- Servo only operates at true level changes

- Communication: Redundant RS 485/20 ma loop Sensing

- Head stows within gauge itself

- Integrated inspection window

- Easy calibration, easy maintenance

- On-board diagnostics

- Tape material: SST.316l, Tefzel coated

- Automatic tape contraction compensation

- ATEX Certified Zone 1, CSA/UL Pending

- Customers can increase the safety and reliability of High Level Alarm detection by using the 2 x SIL 2 Dry-contact relays, available in the 1143 Servo Level Gauge. Depending on the final system architecture, the Safety Integrated Level (SIL) of the LNG tank can reach SIL4 for your application.