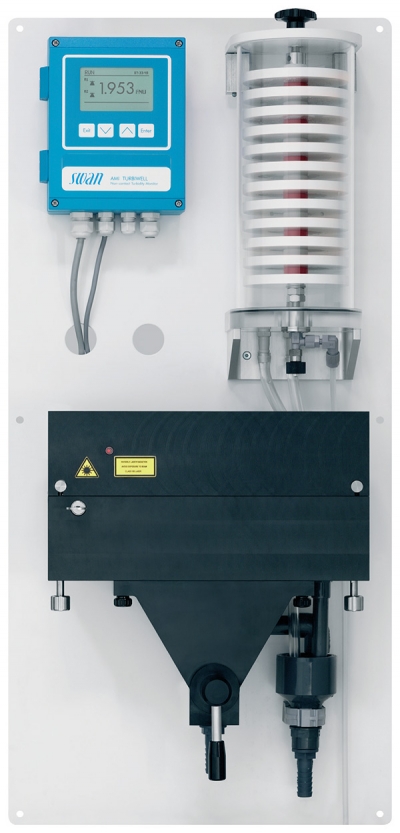

The SWAN AMI Turbiwell water quality turbidimeter is a Nephelometric system, an approved alternative method to US EPA 180.1, for the automatic and continuous measurement of turbidity in potable water, surface water, and effluent.

What makes the SWAN AMI Turbiwell turbidimeter different? Because the SWAN turbidimeter “non-contact” optics are located outside of the water sample, they and are not exposed to fouling/contamination. In addition, continuous lamp intensity and dark current measurements within the analyzer optics ensure that any contaminants that do find their way onto the optical windows or any variations in lamp intensity are automatically compensated for, providing the most accurate and verified measurement value possible.

- Calibrations are not required, an optical verification kit can be provided.

- 4 Year Factory Warranty

- Non-contact turbidity analyzer. System optics are not in direct contact with sample, no fouling on optical surfaces.

- LED lamp source with life expectancy of 10yrs and 50% less power consumption when compared to common Tungsten lamp turbidimeters

- Measuring range: 0.000 - 100.0 NTU Automatic range switching.

- Precision: ± 0.003 NTU or ± 1% of reading.

- Complete system including a transmitter, control electronics, sample chamber and turbidimeter.

- Manual or automatic valve for the drain of the sample chamber.

- Easy user menus in English, German, French, and Spanish. Simple programming of all parameters by keypad.

- Electronic record of major process events and calibration data.

- Real-time clock for timestamp in data logs and for automated functions.

- Data logger for 1,500 data records stored at selectable intervals.

- Big back-lit LCD display for the reading of all measured values and status information simultaneously.

- Measurement values are available as analog output signals or optional Modbus.

- Potential-free alarm contact as summary alarm indication for programmable alarm values and for instrument errors.

- Input for potential-free contact to freeze the measuring value or to interrupt control in automated installations.

- Factory tested, ready for installation and operation